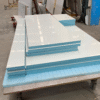

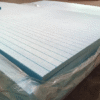

XPS foam core sandwich panels are one of the most popular truck body panel materials. FRP is the most commonly used skin material. The most notable feature of XPS sandwich panels is that XPS foam has the advantages of lightweight, non-absorbent, thermal conductivity, etc., especially in refrigerated trucks, these advantages have been fully utilized.

- Good thermal insulation and heat preservation performance.

- High strength: bonded skin to form a high-strength sandwich panel

- Durable: not easy to corrode or age

- Strong: not easy to deform and compress

- Insulation prevents air from entering and exiting.

- Non-absorbent: a closed-cell structure prevents water absorption.

- Chemically stable and designed for a long service life.

Customization

Surface skin: FRP skin

Size: length ≤12m, width ≤3.2m, thickness: 20mm~120mm.

Density: 25~45kg/m³

Colour customization: yellow, green, blue.

Skin colour: according to RAL

Compressive strength: tuning density and proportion of foaming agent

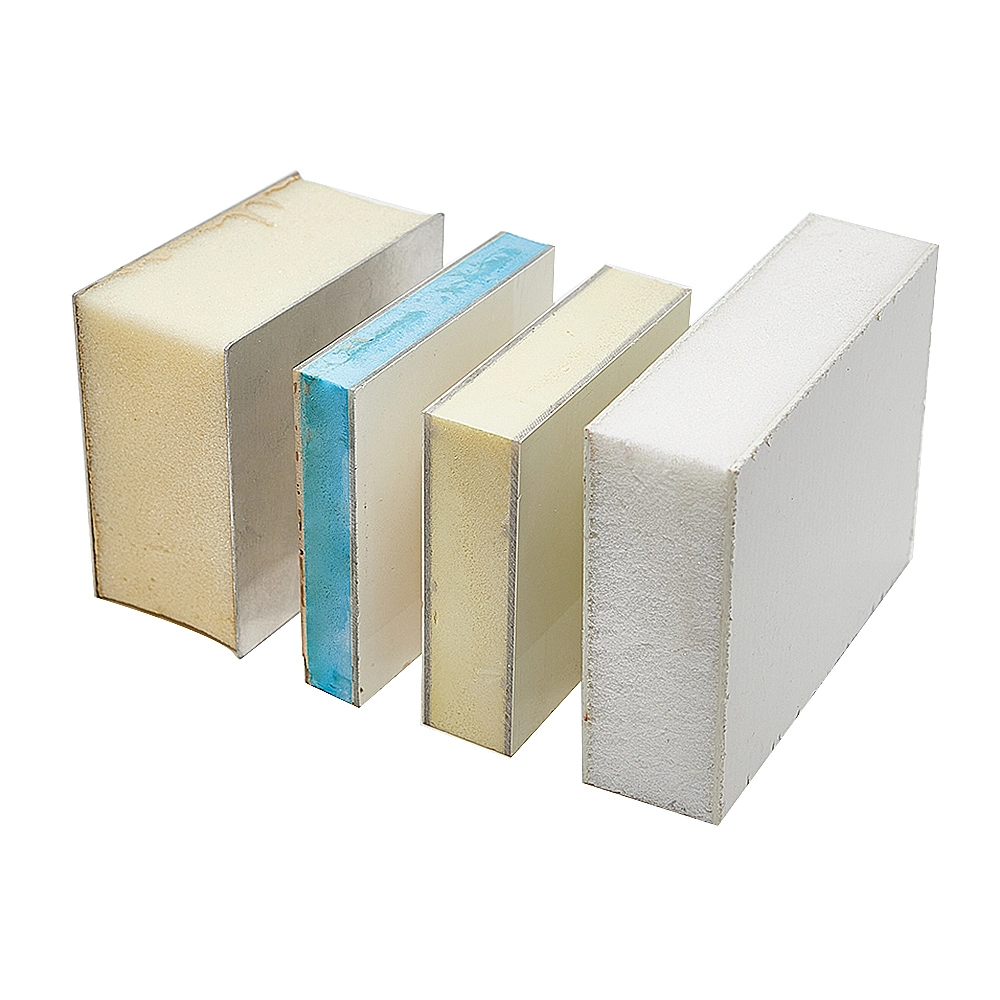

Product Structure

| Parameter | Description |

| Thickness | 10~140 mm |

| Dimensions | Max 360 x 1200 cm |

| Core Material | XPS Foam |

| Skin Material | FRP (0.7~5.0 mm), |

| Core Density | 28~55 kg/m³ |

| Skin Color | RAL Series |

Product Structure

| Parameter | Description |

| Density | 33-50 kg/m³ |

| Compressive Strength | 500-700 kPa |

| Thermal Conductivity | 0.028-0.035 W/(m·K) |

| R-Value | ~5 per inch |

| Water Absorption | <1% (closed-cell structure) |

| Fire Rating | B1/B2 (China standard) |

| Operating Temperature | -50°C to 75°C |

Application