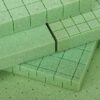

Ltech series is a rigid cross-linked closed-cell PVC structural foam material. It has excellent specific stiffness, specific strength, fatigue resistance, impact resistance and very low water absorption, and can play a role in sound and heat insulation. Cinon series adopts the water suspension foaming process, which makes the foam cross-linked structure complete and the foaming more uniform; it completely avoids the warping of the original board and the internal structure damage caused by hot pressing and leveling. At the same time, it has good dimensional stability and processability, suitable for a variety of sandwich structure manufacturing process, and compatible with a variety of resin systems.

It is the good core material for light weight and high strength composite sandwich structure. The process temperature is -240°C~+120°C, and the long-term use temperature is -240°C~+80°C. The foam is not easily affected by moisture and mildew, and it has good flame retardant properties. Cinon series products are available in densities ranging from 45kg/m³ to 300kg/m³ and are widely used in wind energy, marine, sports equipment, railroad locomotive and aerospace applications.

| Type | Standard | Unit | Result | HX45 | HX50 | HX60 | HX80 | HX100 | HX130 | HX200 | HX250 | HX300 |

| Density | ISO 845 | kg/m³ | Average Value | 45 | 50 | 60 | 80 | 100 | 130 | 200 | 250 | 300 |

| Range | 40-45 | 45-55 | 54-69 | 72-92 | 90-110 | 120-150 | 180-220 | 225-275 | 280-320 | |||

| Compress Strength | ISO 844:2006 | Mpa | Average Value | 0.68 | 0.78 | 0.99 | 1.72 | 2.08 | 3.19 | 5.11 | 6.8 | 8.9 |

| Minimum Value | 0.56 | 0.69 | 0.88 | 1.63 | 1.9 | 2.61 | 4.69 | 6.2 | 7.6 | |||

| Compress E-Modulus | ISO 844:2006 | Mpa | Average Value | 48 | 63 | 87.4 | 135 | 158 | 195 | 313 | 370 | 460 |

| Minimum Value | 36 | 50 | 76 | 122 | 139 | 173 | 274 | 343 | 390 | |||

| Shear Strength | ISO 1922:2012 | Mpa | Average Value | 0.55 | 0.73 | 0.94 | 1.23 | 1.66 | 2.42 | 3.32 | 4.19 | 4.91 |

| Minimum Value | 0.47 | 0.61 | 0.85 | 1.11 | 1.48 | 2.13 | 3.03 | 3.52 | 4.32 | |||

| Shear E-Modulus | ISO 1922:2012 | Mpa | Average Value | 16 | 21 | 27 | 33.9 | 42 | 62 | 83 | 98 | 129 |

| Minimum Value | 14 | 16 | 23 | 28 | 34 | 51 | 72 | 86 | 108 | |||

| Tensile Strength | ASTM C297 | Mpa | Average Value | 0.96 | 1.36 | 1.81 | 2.82 | 3.23 | 4.21 | 5.23 | 7.68 | 9.65 |

| Minimum Value | 0.83 | 1.02 | 1.69 | 2.33 | 2.96 | 3.22 | 4.92 | 6.24 | 8.87 | |||

| Tensile E-Moldulus | ASTM C297 | Mpa | Average Value | 72 | 79 | 96.1 | 149 | 165 | 221 | 296 | 342 | 408 |

| Minimum Value | 63 | 73 | 83 | 128 | 151 | 173 | 238 | 304 | 356 |

*Note: The above data are average results for various products, taken from production routine tests.

Statistical minimum values to meet the design requirements of each classification society are available upon request

Product Characteristics:

• Low water absorption

• High temperature resistance

• High strength and stiffness to weight ratio

• Excellent damage tolerance

• Good chemical resistance

• Sound and thermal insulation

• Impact resistance

• Multiple resin systems compatible

Technical Characteristics:

| Type | Standard | Unit | HX45 | HX50 | HX60 | HX80 | HX100 | HX130 | HX200 | HX250 | HX300 | |

| Themal Conductivity | EN 12667 | W/(m-K) | 0.028 | 0.028 | 0.029 | 0.031 | 0.033 | 0.036 | 0.044 | 0.049 | 0.055 | |

| Linear coefficient of thermal expansion | ISO 4897 | x10-6/°C | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| Thermal deformation | DIN 53424 | °C | +125 | +125 | +125 | +125 | +125 | +125 | +125 | +125 | +125 | |

| Continuous temperature range | / | °C | -200/+80 | -200/+80 | -200/+80 | -200/+80 | -200/+80 | -200/+80 | -200/+80 | -200/+80 | -200/+80 | |

| Dissipation factor | ASTM D 2520 | / | 0.0002 | 0.00024 | 0.0003 | 0.0005 | 0.0006 | 0.0009 | 0.0015 | 0.0019 | 0.0024 | |

| Permittivity | ASTM D 2520 | / | 1.05 | 1.05 | 1.06 | 1.09 | 1.11 | 1.15 | 1.23 | 1.2 | 1.36 | |

| Poisson ratio | D638-08 | / | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | |

*Note: The above data are the average results of various products, taken from production routine tests. Statistical minimum values to meet the design requirements of each classification society are available upon request. Continuous operating temperatures are typically -200ºC to +80ºC. For design use at high temperatures and under continuous load conditions, please contact Technical Services for detailed design instructions.

The maximum processing temperature depends on time, pressure and process conditions. Therefore, it is recommended that the user contact Technical Service to confirm that the specific processing parameters of the Cinon series foams are compatible.

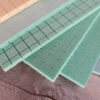

Product Specifications:

| Type | Standard | Unit | HX45 | HX50 | HX60 | HX80 | HX100 | HX130 | HX200 | HX250 | HX300 |

| BLOCK | Length | mm | 2500 | 2400 | 2400 | 2330 | 2050 | 1950 | 1750 | 1480 | 1450 |

| Width | mm | 1250 | 1200 | 1200 | 1150 | 1050 | 980 | 870 | 800 | 750 | |

| Thickness | mm | 90 | 90 | 85 | 75 | 70 | 60 | 50 | 45 | 45 | |

| Contour | Length | mm | 1250 | 1200 | 1200 | 1165 | 1025 | 975 | / | / | / |

| Width | mm | 1250 | 1200 | 1200 | 1150 | 1050 | 980 | / | / | / | |

| Thickness | mm | 5-65 | 5-65 | 5-65 | 5-65 | 5-65 | 5-60 | / | / | / | |

| Plain | Thickness | mm | 1-90 | 1-90 | 1-85 | 1-75 | 1-70 | 1-60 | 2-50 | 2-45 | 2-45 |